Rusted Railway Track Forged into a Beautiful KATANA Karambit Knife Fighting

Guys, Sadly i have to tell you that last two weeks was so tough for me and my team, as most of you know that a hacker hijacked my channel a couple of days ago and that was a big concussion for us but I am happy that you guys keep supporting in that time period. And now i have recovered myself from this incident and Alhamdulilah our channel is back again on its platform.This is the reason, why I am uploading my video after this long time period. This time i need some favour from you guys, share this video as much as you can on all other social media platforms so everyone would come to know that it is not easy to break us down. And with the help of Allah Almighty and support from you guys will make this youtube family more stronger than it was before. When the channel got hacked, I did not stop working i did not lose my hope, spirit and strength, this was all possible because of the love you guys always gave me. And at the end i want you to follow me on the Instagram so everyone will beware of any problem happens in future very closely.

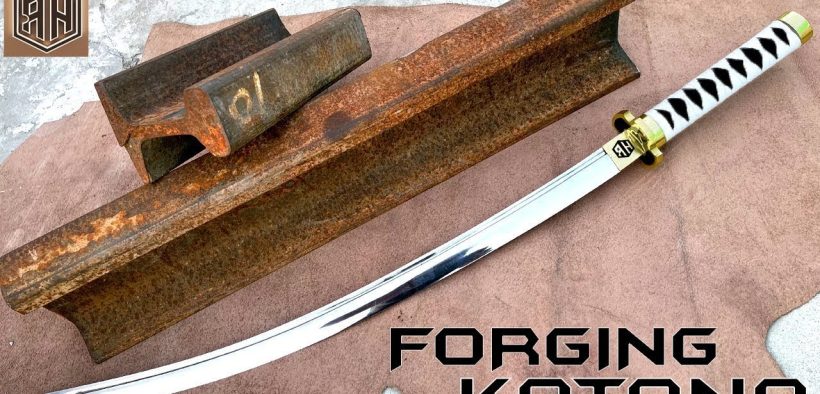

Overall Sword Length : 38.5 Inches

Handle Length : 9.5 Inches

Blade Length : 29 Inches

All the Processes are below of making this beautiful KATANA:

Forging:

It took me almost a week to hand forge an Iron railway track piece into a long Metal Strip and this was one of my hardest forging ever. I don’t have a power hammer so i did all the forging with hands and turned a railway track piece into an almost 35 – 40 inches long steel strip.

Grinding:

I started all the grindings of long strip on my SURFACE GRINDER and turned the forged strip into a Katana shaped long steel piece. I also hand sanded the edges with the help of file to remove almost all the roughness of the sword.

o. I made the Blood Groove with the help of dewalt roater.

o. The blade bevel was made by my professional angle grinder and 2×82” Belt grinder.

o. Hand Sanded the blade to remove roughness.

Hardness:

There is a professional way to harden a Katana and that is

Covering the whole sword in a Fire Clay (Insulation) Except the blade bevel.After that we put the sword into the fire and heat it to critical temperature. We use oil to Quench the heated sword in it. Now the Bevel is hard and the remaining sword is annealed. Tempering the blade is the best way to increase the Strength, Hardness and Toughness of the sword.

Hibaki:

This piece is traditionally made by forging some copper or brass but we can also make it by casting these metals. And the purpose of hibaki is to hold the Sheath with the handle.

Handle:

The Handle contains three parts.

o. TSUBA: I made the guard by Wax casting technique and also used some black epoxy resin to make it more beautiful. Tsuba shows a partition between the handle and the remaining sword.

o. Spacer: This is the little metal piece which fits on tang and controls the fittings of the whole handle so nothing should vibrate in handle.

o. TSUKA: A nice piece of wood uses as a handle/ tsuka of the sword and that could be Wrapped by some soft Silk or leather strips.

Rusted Railway Track Forged into a Beautiful KATANA

#Forging

#RandomHands

Precautions:

Always wear leather gloves while sanding knives. Always keep a First Aid Kit at your work place.

Stay connected :

Our Instagram = https://www.instagram.com/random.hands/

Youtube Channel = www.youtube.com/randomhands

Our Facebook = https://www.facebook.com/randomhands

Youtube Subscription:

https://www.youtube.com/channel/UCrI3dm4qgAEV67Jc6797WIA?sub_confirmation=1

Like, Subscribe & SHARE the video also comment your opinions.

Hope you Enjoyed the Video. See you Next time. Subscribe for more interesting projects.

Also Share the video with your friends who might be interested.

Thanks for watching

Best wishes

Random Hands

source

Karambit Knife Fighting